Cut Angle and Plating Combined,

Framing Member Calculations (English Units)

Description:

This boilerplate template performs combined member area

property calculations. They include the property effects of the

cut angle framing member and also the plating to which this framing member is attached.

-

These calculations assume that a reference is

available that will provide the necessary area properties of the

framing member for insertion into this electronic calculation sheet for

computing the combined effects with plating attached.

-

This MathCAD document calculates the available

area properties such as section modulus and moment of inertia. It

does not calculate the required section modulus which is obtained

from sources similar to Reference B through D. In other words two

sets of calculations are needed. First the required section

modulus needs to be computed. Then some available framing members

are selected and their combined properties are computed on a electronic

document, like this template, to see if the available members meet or

exceed the required area properties.

-

This template applies to a frame that is cut to

accommodate a smaller framing member penetrating through it. These

computations deduct the area property effects of the material lost in this

notch.

-

The effective plating width, EPW, selected is the lesser

of the ABS allowable [1983 Rules for Steel Vessels under 200 feet (61

meters)], 38 times the plating thickness (an industry rule of thumb), or

the frame spacing (limited by geometry in this case). If other

classification society classing rules apply, these calculations should

be modified to suit applicable the classification society requirements.

-

These calculations apply to English units. But the

purchaser may change the template to apply to metric units.

-

The material for the framing member must be the same as for the plating member. Another approach is necessary

if this is not the case. In other words, this approach will work

for a steel frame on steel plating or an aluminum frame on aluminum

plating. It will not work for a aluminum frame on steel plating or

a steel frame on aluminum plating.

There are advantages and benefits to this calculative

method. First this approach saves you time. Many

computations are quickly done on your input data.

Second this approach provides clear and neat

documentation. These computations can readily be submitted to U. S.

C. G. or classification societies if requested. Third this approach

is cost effective because the calculative approach is already developed

for you, research time is minimized to familiarization of concepts if

necessary and not to time consuming development activities.

Electronic

Document Type: MathSoft

MathCAD

document Cost:

$7.50 US funds

Number of

Pages: Inputs Page, Outputs Page (2 MathCAD pages). Instructions

and Use Terms Page (1 browser page).

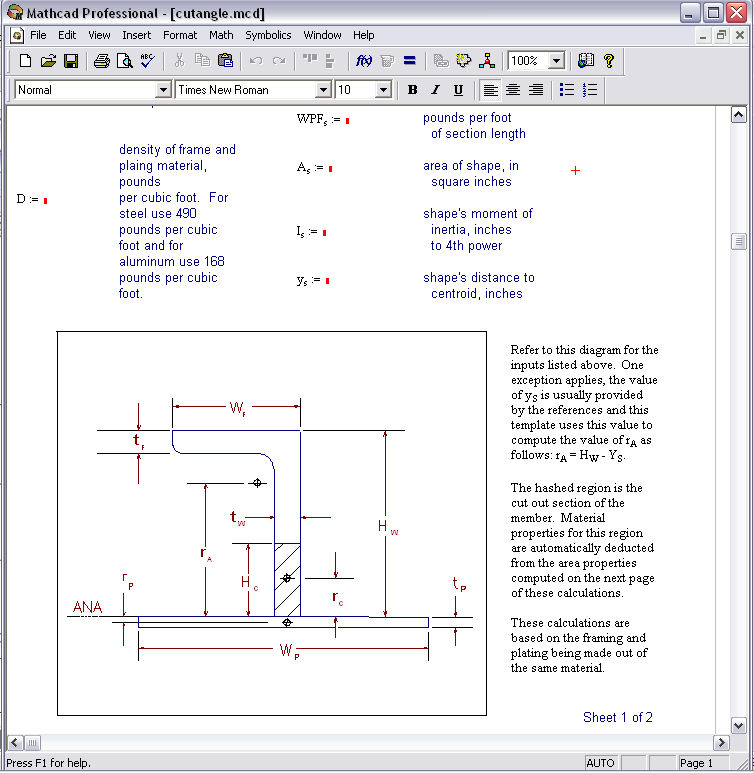

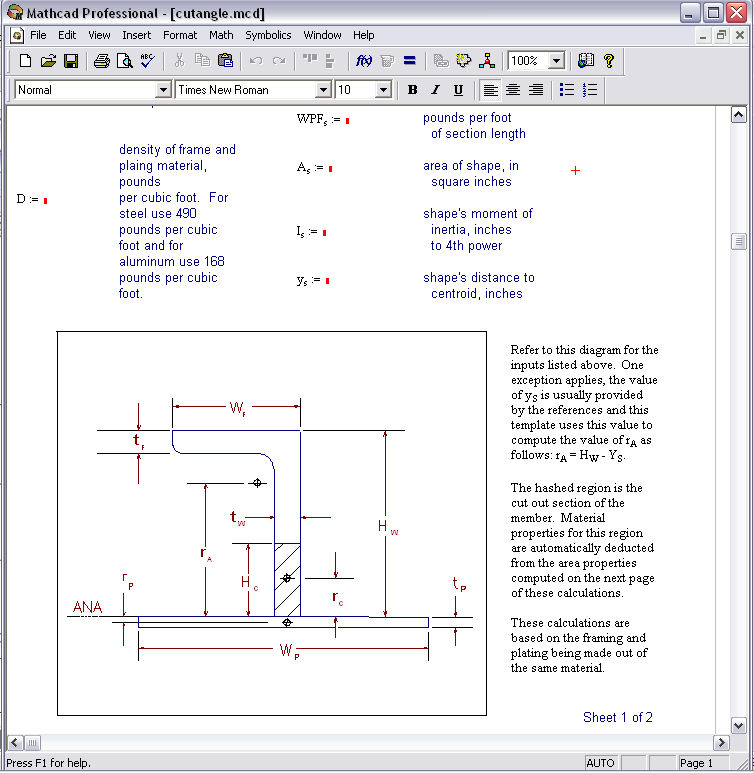

Inputs:

-

Geometric Properties of Framing Assembly

-

Support Length (or span) of framing member, inches

-

Support Width of framing member, inches

-

Height of Cut into framing member, inches

-

Angle Framing Member Properties, from reference texts,

diagram provided

-

Height of Web, inches

-

Thickness of Web, inches

-

Width of Flange, inches

-

Thickness of Flange, inches (if different from web

thickness)

-

Area, square inches

-

Area Centroid Distance, inches

-

Moment of Inertia, inches4

-

Unit Weight, pounds per foot

-

Plating Properties

-

Material Properties

Outputs:

Recommended

Reading:

Reference A: AISC Steel Construction Manual,

American Institute of Steel Construction, Chicago, IL.

-

Reference B: ABS Rules for Building and

Classing Steel Vessels Under 210 feet (61 meters), 1983, American

Bureau of Shipping, Houston, TX.

-

Reference C: Arthur Edmunds, Designing for

Power and Sail, Bristol Fashion Publications, 1998, Harrisburg, PA.

-

Reference D: John S. Spencer, Structural Design

of Aluminum Crewboats, Marine Technology, July 1975 Issue, Society

of Naval Architects and Marine Engineers, Paramus, NJ.

-

Reference E: Bruce Roberts-Goodson, The

Complete Guide to Metal Boats, International Marine, 2001, Camden,

ME.

-

Reference F: Dave Gerr, Boat Strength for

Builders, Designers and Owners, International Marine, 2000, Camden,

ME.

-

Reference G: Rawson and Tupper, Basic Ship

Theory, Longhams, London

-

Reference H: SNAME, Principles of Naval

Architecture, Society of Naval Architects and Marine Engineers,

Paramus, NJ.

-

any strength

of materials text

Terms:

Prior to purchase, read our End

User License Terms.

Download

Now: click the following hyperlink to pay

$7.50 fee and then immediately download the zip file containing the template.

Minimum

System Requirements: Windows 95/98/NT/2000/XP/Vista/Windows7

Sample:

A sample portion of a page is shown below.

|